Selecting a Process Heat Exchanger for Your Application.

Shell-and-tube heat exchangers — first introduced in the 1900s — have long been used in all types of process applications because of their robust design. Shell-and-tube heat exchangers are able to withstand high pressures and temperatures, and these features are among the reasons for their wide use.

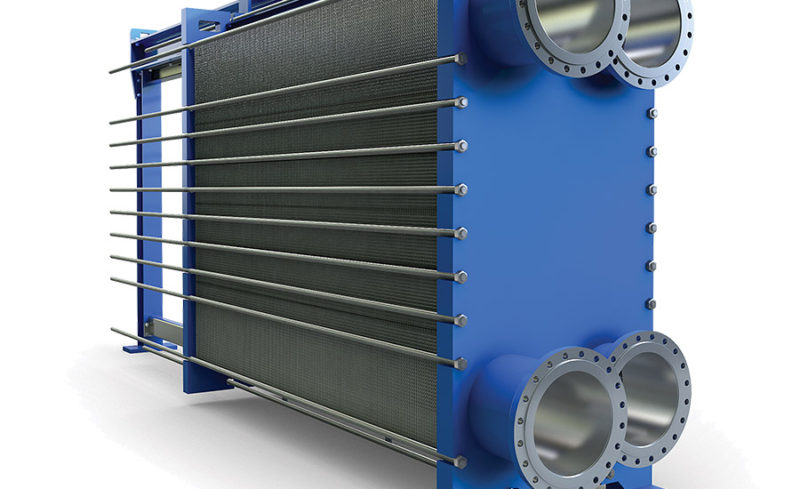

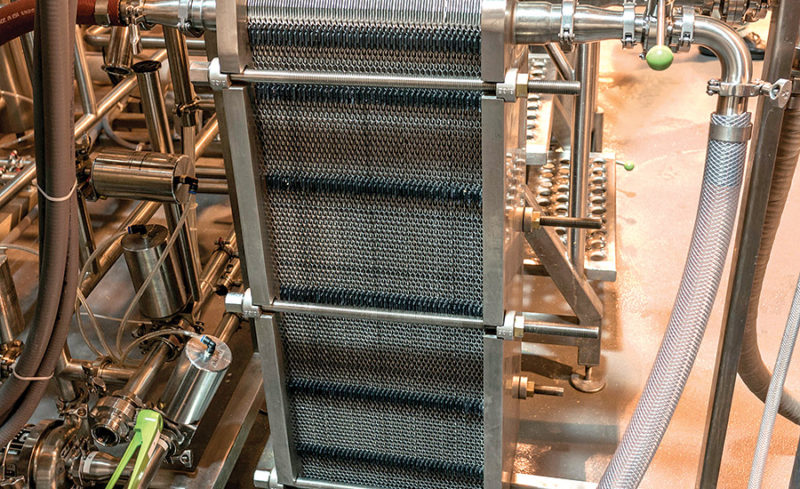

More recently, plate-type heat exchangers have become increasingly popular due to their high efficiency and small footprint. Plate-type heat exchanger designs are constructed by stacking several layers of corrugated plates to create a series of channels though which liquids flow. This high efficiency design allows the units to be smaller in size and requires less fluid content than shell-and-tube units of the same capacity. By nature of the design, plate heat exchangers provide good heat transfer.

A hybrid — a plate-and-shell design — combines the high pressure and temperature capabilities of a shell-and-tube heat exchanger with the efficiency and reduced footprint features of a plate heat exchanger. The hybrid design is allowing some processors to replace shell-and-tube units with a plate-and-shell design that offers improved heat transfer efficiency.

A closer look at the options explores the advantages of each design. Keep in mind that selecting the best heat exchanger for a process application depends on many factors, including operational design parameters, fluid compatibility, approach temperatures, space allocation and budget.

The most common type of plate-and-frame heat exchanger is a gasketed plate-and-frame design.

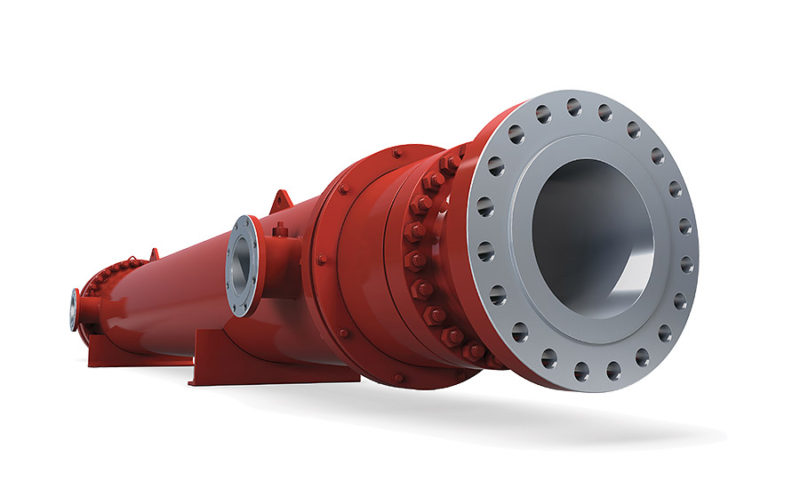

Shell-and-Tube Design

Most people are familiar with the shell-and-tube design. In this type of heat exchanger, a bundle of small-diameter tubes is encased inside a large-diameter cylinder or shell. As mentioned earlier, one of the main advantages of this design is its ability to withstand high operating pressures and temperatures.

Another advantage of the shell-and-tube heat exchanger is its serviceability. In some services, however, the tubes can be fouled easily. Such fouling diminishes overall system efficiency.

A shell-and-tube design is the largest type of heat exchanger, so ample floor space is required. Due to its large size and the amount of material needed to construct it, the initial cost can be higher than other heat exchanger options.

Most people are familiar with the shell-and-tube design. In this type of heat exchanger, a bundle of small tubes is encased inside a large cylinder or shell. One of the main advantages of this design is its ability to withstand high operating pressures and temperatures.

Plate-and-Frame Design

Plate-and-frame heat exchangers are offered in several assemblies. The most common one is a gasketed plate-and-frame design.

In a gasketed plate-and-frame design, a synthetic rubber gasket is placed between the plates to form fluid channels. This design can be limited with regards to temperature, pressure and fluid compatibility due to the operational limitations of the gasket material. Generally, the maximum temperature limit is 392°F (200°C), and the maximum design pressure limit is 400 psi. With the exception of dairy and sanitary applications, these operating parameters typically are too low for most processing environments.

If the design parameters for a process application accommodate a gasketed plate-and-frame design, it is also important to confirm that the fluids traveling through the unit are compatible with the gaskets. The gasketed plate-and-frame exchanger assembly offers a design that is easily cleanable, and the fouled plates are simple to replace.

A second option for a plate-and-frame design is an all-welded unit. Because it is constructed without gaskets, this design does not have the temperature and pressure constraints of a gasketed design. Welded plate exchanger designs are used in many process applications.

In addition to its higher operating design parameters, the all-welded design provides good corrosion resistance. Compared to gasketed plate designs, the all-welded units require more effort to clean. They are not very susceptible to fouling and can provide long-term serviceability when properly maintained. Also, with the all-welded design, there is no chance of leaking, which can be an issue — albeit small — with a gasketed design.

Plate-and-Shell Design

In this design, a fully welded plate pack is inserted into a shell, which distributes the stress and eliminates the need for gaskets. This type of heat exchanger can withstand extreme temperatures and pressures. It operates with liquids, gases or transitioning phases of the two.

A plate-and-shell unit often is designed and manufactured to meet a customer’s specific needs, and the type of metal used is dictated by the application. Stainless steel is the norm although titanium is used when a highly corrosive fluid such as hydrochloric acid is involved in the process.

Unlike a shell-and-tube design, there is little chance of fouling in a plate-and-shell design. Instead, these units are almost always self-cleaning: When running fluids through plate-and-shell units, the higher the velocity of operation, the cleaner the plates. Tubes do not have as many self-cleaning properties and are thus susceptible to fouling.

Many refineries are retrofitting their equipment to plate-and-shell designs. Laser-welded packs can be retrofit in place of the tube bundles in existing exchanger shells. Because the plate packs are smaller than the bundles, plants close off (via welding, for instance) a section of the shell. The resulting process offers higher efficiency in a smaller footprint. These plate-and-shell exchangers can be less expensive to operate than the shell-and-tube they replace due to reduced energy demands.

A laser-welded plate-and-shell heat exchangers can be used for thermal treatment of liquids, vapors or gases.

Plate-and-Shell Design for Steam

A recent installation can illustrate some of the benefits of retrofitting a plate-and-shell exchanger design in a process application.

A chemical company reached out to several exchanger manufacturers seeking a single exchanger that could be used to both condense process steam and subcool steam. Engineers at one heat exchanger manufacturer designed a unit with high efficiency plates in a double-plate pack. They positioned the packs back-to-back in the shell with double, openable ends. Extensive testing demonstrated the exchanger performance and allowed the project to move forward.

Typically, two separate pieces of equipment are required to condense process steam and subcool steam. In the new design, the two plate packs allow for two inlets and two outlets on the plate side. This results in twice as much cold water going into the inlet. Feeding a large amount of cold water into the unit at the start of the system ensures that the unit maintains the environment needed for thermal condensing.

At the same time, the unit is designed to cool steam with cooling tower water. As a result, the unit can condense and subcool steam in one piece of equipment. In the new design, steam condenses in one unit and moves from the outlet into another unit that subcools it.

The equipment is now operational, and the chemical company executives are pleased with the results. There has been a reduction in the facility’s operating costs because less chilling is required before the heat exchanger due to the high efficiency of the plate thermal transfer. In addition, according to the chemical company executives, the maintenance staff appreciates that the double, openable ends that ease serviceability.

In conclusion, although there are several types of heat exchangers, the purchase decision often can be narrowed down by the temperatures and pressures required for the process. Other factors to consider include equipment footprint and approach temperature. These go hand in hand: The smaller the approach temperature, the larger the unit. Shell-and-tube units typically do not work well with approaches of less than 20°F (11°C), so for those applications, plate heat exchangers may be a better fit.

Remember that the process requirements for plate-and-shell applications generally are customer specific. Plates are supplied in many sizes, and the exchanger dimensions (number of and size of plates, gasket material, etc.) can be tailored to a customer’s operation. Such customization does not necessarily mean a long timetable or a higher upfront cost. Solutions can be tailored from standard product lines to satisfy process requirements in a range of industries.