Gland Steam Condensers

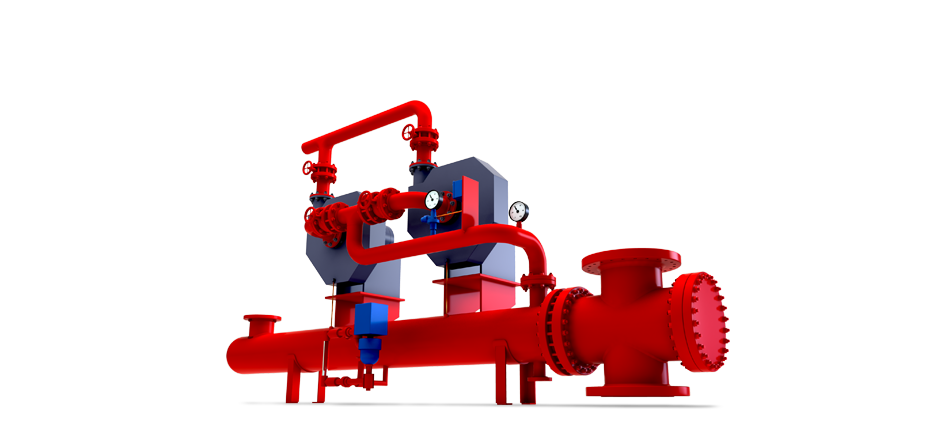

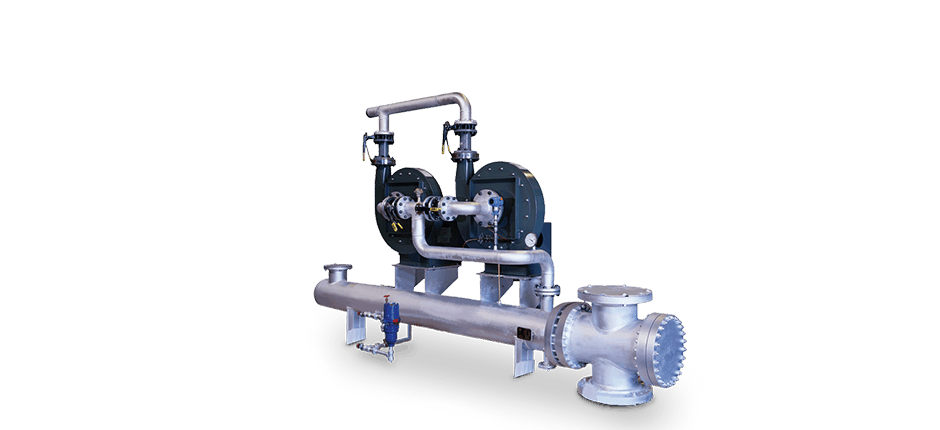

Basco® Gland Steam Condenser Packages

Gland steam condensers are essential for improved efficiency in steam turbine systems. Our gland steam condenser packages come in almost every possible configuration, allowing us to supply complete systems to major steam turbine OEMs around the world.

Performance Notes

Our gland steam condenser packages pull a slight vacuum on the turbine shaft seals by means of vacuum pumps, centrifugal blowers, or steam ejectors. This captures the leaked steam and air mixture. Once collected, the steam is separated from the air and condensed in a shell and tube condenser. The condensate drains out of the bottom while the air is pulled out of the top. The condensed steam is then sent back to the steam cycle with the other condensate.

We offer instruments to help monitor process conditions, including the amount of vacuum, outlet air temperature, and condensate drainage. And while many manufacturers can only supply the condenser, API Heat Transfer can provide the complete system – saving you time and ensuring maximum efficiency.

Applications

- Power Generation

- Power Generators

- Power Plant Equipment

| Sizes | Diameter 3 to 42 in. (75 to 1050 mm); length 12 to 360 in. (305 to 9150 mm) [available in 6 in. (150 mm) increments] [verfügbar in Schritten von 150 mm] |

| Shells | Carbon steel, 304 stainless steel, or 316 stainless steel |

| Tube Sizes | 3/8 in. (10 mm), 5/8 in. (16 mm), or 3/4 in. (19 mm) diameter |

| Tube Materials | Carbon steel, copper, Admiralty, 90/10 or 70/30 CuNi, 304 stainless steel, 316 stainless steel, 2205 stainless steel, titanium, and other high-alloy materials |

| Tube Configuration | Straight tube, U-tube |

| Baffles | Precision-punched carbon steel, brass, stainless steel |

| Heads | Channels and bonnets in steel and stainless steel |

| Flow | 1-pass, 2-pass, 4-pass designs for fixed bundles |

| Codes | ASME, PED, ABS, TEMA, USCG, API611, API612, others |