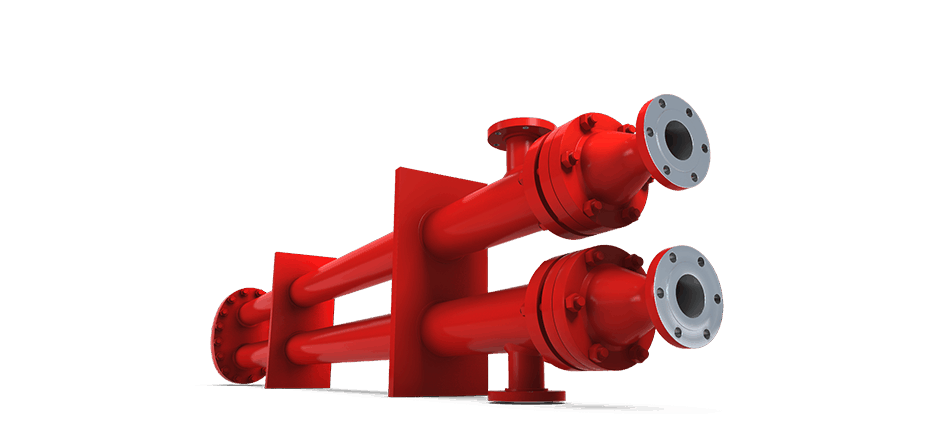

Hairpin

Basco® Hairpin Heat Exchangers

A hairpin design is often more thermally efficient than a traditional shell and tube, which results in a lower up-front cost and lower overall weight. Our experienced designers and engineers can meet any custom cooling requirement.

Removable Bundle Types.

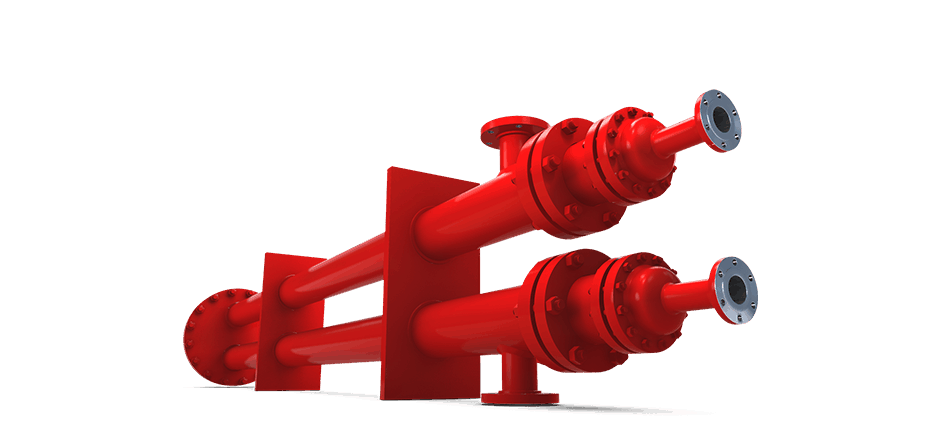

Separated Closure Double Pipe: Type SCDP

- Employs the industry’s most widely used separated head features

- Shell side and tube side closures are separately bolted through, ideal for applications involving wide temperature or pressure differences between the shell and tube side fluids

- In cyclic service, separately gasketed closures are more leak resistant compared to shell and tube designs

- Separate shell and tube side seal configuration. This makes the tube bundle easy to remove, clean and replace.

- Well suited for large imbalance of flow on shellside

- Long fins are used to achieve high thermal performance with minimal pressure drop

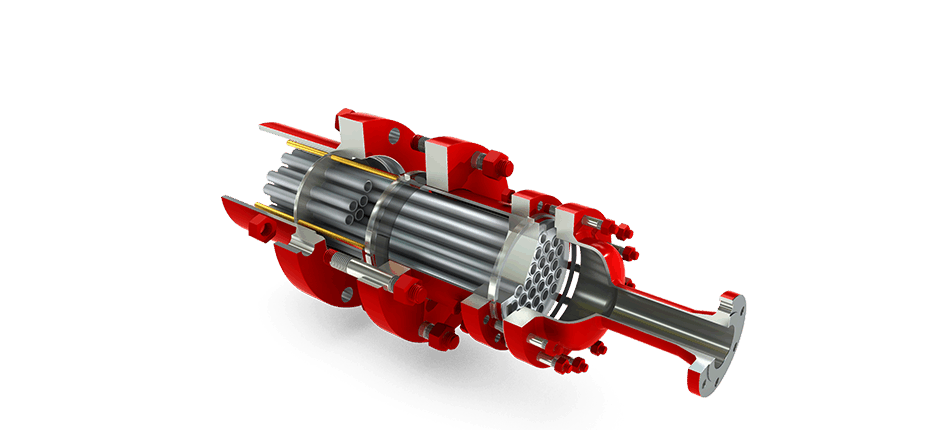

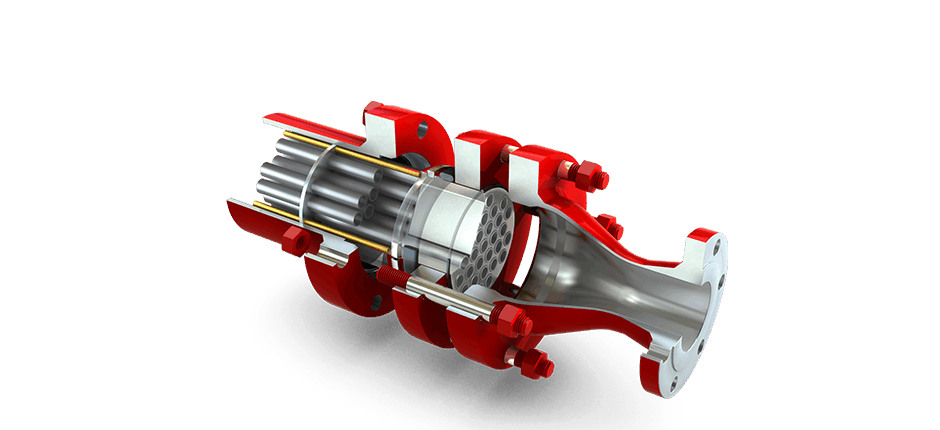

Common Closure Hairpin: Type CC

- Single bolted closure design. Ideal for applications involving low design temperature or pressure differences between the shell and tube side fluids

- Enjoys the maintenance advantages of a Separated Closure Hairpin (Type SC)

- The center ring keeps the shell gasket seated during the removal of the tube head for inspection or service

Non-Removable Bundle Types.

All-Welded Hairpin: Type AW

- More cost effective design when removable bundle is not required

- Fixed tubesheet design

Jacketed Pipe: Type JP

- Most economical solution for any heat transfer application

- Fixed tubesheet design

Performance Notes

- Ideal for applications that require high thermal performance and a compact footprint

- True countercurrent flow allows for a close temperature approach between the shell side and tube side fluids, as well as a temperature cross

- Removable bundles are available in two closure options, separated or common, for required cleaning on both the shell and tube sides

- Non-removable bundles are the cost-effective option when a fixed tubesheet design is feasible

- Wide temperature differentials are handled without an expansion joint

- Ease of maintenance with a long radius U-bend

- All connections are at one end of the heat exchanger

- Sizes up to 60 in. (150 cm) in diameter and 480 in. (1200 cm) in length

- Materials include carbon steel, 300 series stainless steel, Duplex stainless steel, copper alloy, chrome-moly alloys, Hastelloy, Inconel, Monel, 254 SMO, alloy clad/weld overlay

- Designed and fabricated per ASME, TEMA, CRN, PED, CML

Applications

- Oil and Gas

- Process Industries

- Chemical

- Petrochemical